RV reducer breaks through technically

RV reducer is one of the three core components of industrial robots. At present, reducers in the Chinese market generally rely on imports. Due to the complex structure of the RV reducer and the difficulty of processing, enterprises with many years of precision machining experience can master it. The design and manufacture of the reducer involves material heat treatment, parts micro-processing, precision assembly and other technologies that require long-term experience to explore and accumulate, and the technical barriers are extremely high.

Most of the robotic RV reducers currently used in the market are imported from abroad. Ordinary RV reducers are often complicated in structure, large in size, difficult to process, and require many considerations in design, high cost, and produced between components. The friction and wear are large, and the clearance is also large. Therefore, its transmission performance is poor, its transmission efficiency is low, and its service life is short, which seriously restricts the development of China's robot and equipment industry.

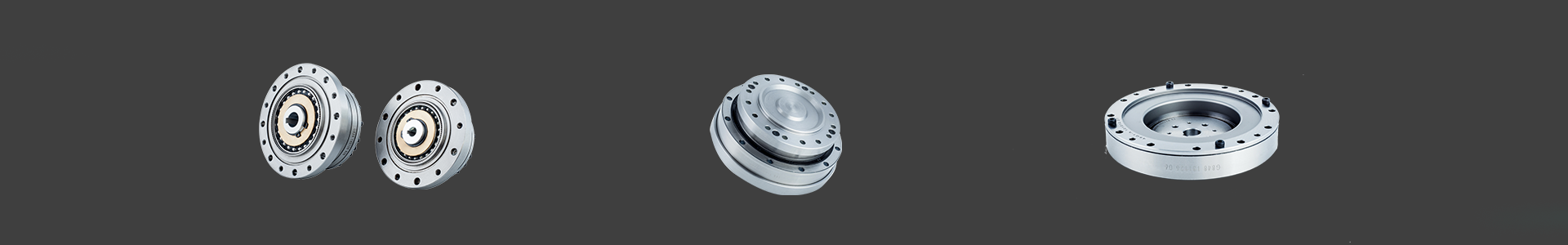

Since its introduction in 1986, the RV reducer has become an indispensable core component for reliable and accurate operation of industrial robots. It is a planetary transmission principle that uses a cycloid pin-to-gear reduction transmission mechanism. , Light weight, large transmission ratio, high load carrying capacity, strong applicability, high safety and reliability, etc., widely used in industrial robots, automated packaging, precision medical equipment and many other industries and fields of mechanical gear reducer.

After years of investment and research and development, the core technology of the RV reducer has been continuously upgraded. Based on the accumulation of the original technology, a new RV reducer has been successfully developed. Extend product life.