How does the harmonic reducer solve the noise problem?

Data:2020-06-05 09:01:15 Views:

The harmonic reducer supplier teaches you how to solve the noise problem of the reducer:

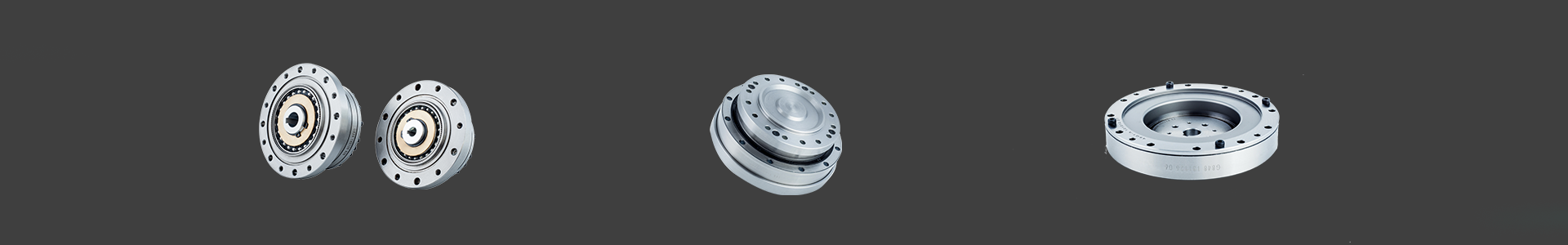

First of all, everyone knows that planetary reducers, servo reducers, 90-degree servo reducers, harmonic reducers, right-angle reducers, high-precision reducer hollow rotating platforms, corner planetary reducers, robot joint RV reducers and other reducers will have Noisy, but there will be a relevant decibel value. The noise is mainly caused by the friction, vibration and collision of the transmission gear. How to effectively reduce the noise? What problems should we pay attention to during the use? This article introduces the use and maintenance of the reducer noise.

1. Timely lubrication and proper use of oil

Unreasonable lubrication and incorrect use of grease will cause incalculable damage to the reducer. At high speeds, the friction of the gear tooth surface will generate a lot of heat energy. Improper lubrication will cause damage to the gear teeth, affect accuracy, and increase noise. The design requires that the gear pair has a proper clearance (the clearance between the non-working surfaces of the meshing gear teeth to compensate for thermal deformation and store grease). The correct use and selection of lubricating grease can ensure the safe and effective operation of the system, delay the deterioration trend, and stabilize the noise level.

2.the correct use

Proper use of the reducer can minimize the damage and damage of parts and ensure a stable noise level. The noise of the reducer will increase with the increase of the load, so it should be used within the normal load range.

3. Regular maintenance and repair

Regular oil change, replacement of worn parts, loose parts of fasteners, removal of internal debris, gear box cleaning and maintenance machine can use the original oil supply and discharge system of the gear box and filtered old oil to achieve the gear box The functions of cleaning, rapid filtering of waste oil, and filling of new oil, etc., do not change the hardware facilities and do not add cleaning agents during the operation process, ensuring the safe operation of the gear box and extending the service life. Adjust the clearance of each component to the standard specified value, verify the geometric accuracy of each item, etc. Combining the above three points can improve the reducer's ability to resist noise level degradation and maintain a stable use state.