The fundamental difference between RV reducer and harmonic reducer!

Data:2020-06-05 09:00:24 Views:

Industrial robots can be divided into SCARA robots, rectangular coordinate robots, articulated robots, parallel robots and others according to their mechanical structure. The global industrial robot market is mainly articulated industrial robots. The robot is composed of a controller, a servo motor and a reducer. Among them, the reducer of the three core parts, the cost of the servo and the controller account for 30%~50%, 20%~30%, 10%~20% of the robot cost respectively. The reducers used in industrial robots mainly include RV reducers and harmonic reducers. How to distinguish between uses?

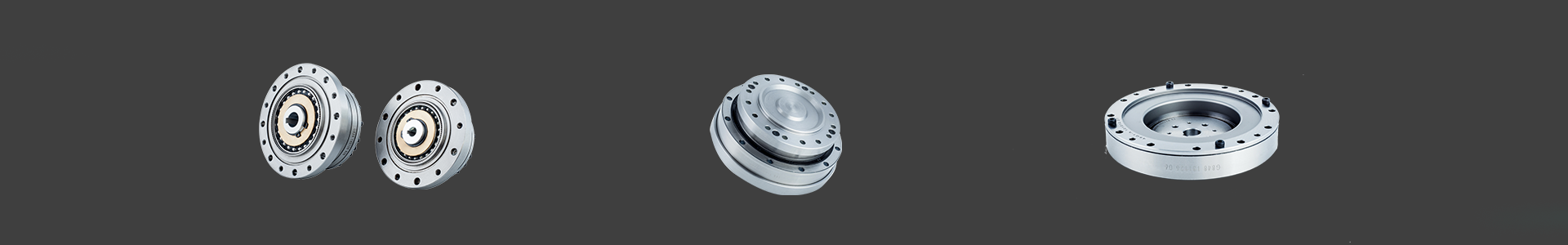

The reducer is divided into harmonic reducer and RV reducer.

The RV reducer has the following characteristics: The key to the RV reducer is the processing technology and assembly technology. RV reducer has higher fatigue strength, stiffness and life. Unlike harmonic drive, the use of time increases, the accuracy of movement will be significantly reduced, its disadvantages are heavy weight and dimensional tolerances.

The upper harmonic reducer is used for several axes at the end of a small robot or a large robot. It is characterized by small size, light weight, large carrying capacity, high motion accuracy, and large single-stage transmission ratio. In the field of reducers, the current global market share is as high as 80%. In the industrial development of domestic harmonic reducers, at the speed of green development, it has been supplied with some domestic robots and even many foreign robot manufacturers for trial use. It is expected to exceed 30,000 units this year, and its market share in domestic harmonic reducers exceeds 60%.

It can be known from the above that RV reducers are mainly used for heavy-duty robots, concentrated in the first few joints, and harmonic reducers are mainly used for light, small industrial robots.