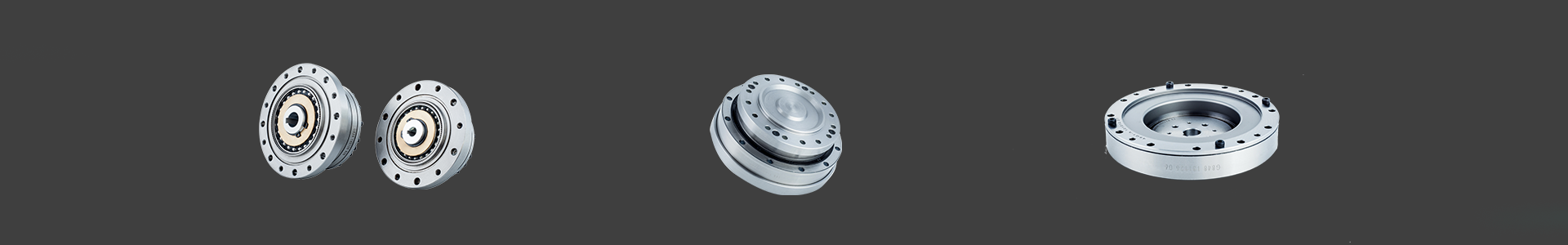

Special harmonic reducer for robot

Data:2020-06-18 13:15:32 Views:

Wave generator

The part of the oval cam with a thin-walled ball bearing embedded in the outer periphery. The inner wheel of the bearing is fixed on the cam, and the outer wheel is elastically deformed by balls. Usually installed on the input shaft.

flexible wheel

Metal elastomer parts with thin-walled cups. A gear is engraved on the outer periphery of the opening. The bottom of the flexible wheel (the bottom of the cup) is called the diaphragm and is usually mounted on the output shaft.

Ganglun

Rigid body ring parts. The inner circumference is engraved with gears, which have two more teeth than the flexible wheel. Usually fixed on the housing.

1. High reduction ratio

Single-stage coaxial can obtain a high reduction ratio of 1/30~1/320. The structure and structure are simple, but the device with high reduction ratio can be realized.

2. Small backlash

HarmonicDrive is different from meshing with ordinary gears. The backlash is extremely small. This feature is an indispensable element for the controller field.

3. High precision

Multi-tooth meshing at the same time, and there are two 180-degree symmetrical gears meshing, so the impact of gear pitch error and cumulative pitch error on the rotation accuracy is more average, so that the position accuracy and rotation accuracy reach an extremely high level.

4. Fewer parts and easy installation

The three basic components achieve a high reduction ratio, and they are all coaxial, so the kit is easy to install and simple in shape.

5. Small size and light weight

Compared with the conventional gear device, the volume is 1/3 and the weight is 1/2, but the same torque capacity and reduction ratio can be obtained, and the size and weight are reduced.

6. High torque capacity

Flexible wheel material uses special steel with high fatigue strength. Unlike ordinary transmissions, the number of teeth that mesh simultaneously accounts for about 30% of the total number of teeth, and they are in surface contact, so that the pressure on each gear becomes smaller and a high torque capacity can be obtained.

7. High efficiency

The gear tooth meshing part slides very little, reducing the power loss caused by friction. Therefore, while achieving a high reduction ratio, high efficiency can be maintained and the drive motor can be miniaturized.

8. Low noise

Gear teeth have a low meshing peripheral speed, which transfers the balance of motion power, so the operation is quiet and the vibration is extremely small.

Suzhou Industrial Park Dongmao Industrial Equipment Co., Ltd. is market-oriented, backed by strength, advancing with the times, pioneering and innovating, and constantly exploring Japanese RV reducers, robot-specific reducers, Bonfiglione reducers, Xinbao reducers, Japan Xinbao reducer, harmonic reducer, Italian Bonfiglioli reducer, BONFIGLIOLI reducer, shimpo reducer, Teijin reducer, ROSSI reducer, Japan Teijin reducer, Rossi reducer, Italy Rossi reducer, DYNABOX reducer, Rorcy reducer and other precision transmission equipment market space, build a sustainable development strategic platform, with excellent products and quality service, sincerely reward users.

We have always adhered to the service tenet of "customer first, reputation first", pursued the business philosophy of "people-oriented, honesty", adhering to the development idea of "only professional, only to become a career", and dedicated to providing new and old users with high-quality products and Excellent service. Sincerely welcome your call, the company is willing to be honest with you, sincere cooperation, and jointly open the source of benefits.