What are the gear transmission methods of harmonic reducers?

Data:2020-06-18 13:23:05 Views:

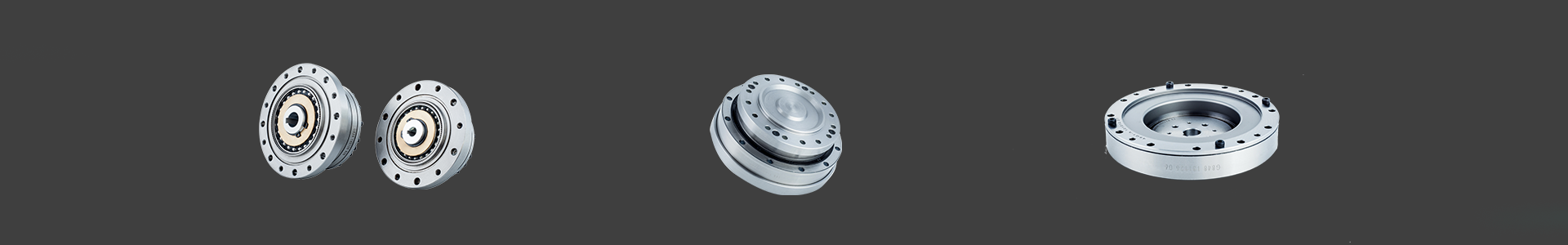

What are the gear transmission methods of harmonic reducers? Harmonic reducer has a series of advantages such as large transmission ratio, simple structure, small size, light weight and high precision. Harmonic gear transmission technology and devices are widely used in radar communications, industrial robots, precision machine tools, instrumentation, textile printing, precision optical equipment, medical equipment and other fields. So what is the type of harmonic drive and what are the classifications?

1. According to the action principle of flexible wheel and wave generator, it is classified into electromagnetic coupling type and mechanical connection type.

The deformation force of the electromagnetic coupling type flexible wheel is generated by the electromagnetic coupling between the wave generator and the uniform device in the coil on the circumference of the flexible wheel. The mechanical connection type causes the flexible wheel to move by mechanical force.

Second, according to the configuration of the harmonic reducer wave generator relative to the flexible wheel, it is classified into an external wave generator and an internal wave generator.

The external wave generator has a large structure size and a large rotational inertia, so it is not suitable for high speed. When the fixed deformation wave generator is used, the internal type is generally used.

3. According to the transmission form, it is classified into end-face harmonic gear drive, radial harmonic gear drive and harmonic spiral drive.

Harmonic gear drive with end face is a type of space toothed transmission. The axial dimension of this type of transmission is small and the torsional rigidity of the flexible wheel is large. Radial harmonic gear transmission belongs to the type of flat meshing and is currently the most widely used.

4. According to the deformation wave number, it is classified into single wave, double wave and triple wave transmission.

Harmonic reducer gear transmission wave number refers to the number of cycles that a wave generator rotates once and a certain point on the flexible wheel deforms. The deformation of the flexible wheel driven by a single wave gear is asymmetric, so the design requirements for the tooth profile and the convex contour of the wave generator are too high. The difference between the number of teeth of the flexible wheel and the rigid wheel of the double-wave gear transmission is 2, the structure is relatively simple, and it is the most commonly used. The three-wave alignment is good, and the eccentricity error is small, but the processing is complicated, and the number of repeated bending of the flexible wheel increases, so the fatigue life of the flexible wheel is relatively low. Generally seldom used.

With the development of the times, industrial intelligent robots, medical equipment, radio communications, CNC machine tools and other equipment are constantly updated, and the requirements are constantly increasing. Then the transmission requirements for harmonic reducers will also be higher and higher. Classification helps to select and use a more suitable type of harmonic reducer.