What is the transmission principle of harmonic reducer?

Data:2020-06-18 13:25:01 Views:

What is the transmission principle of harmonic reducer?

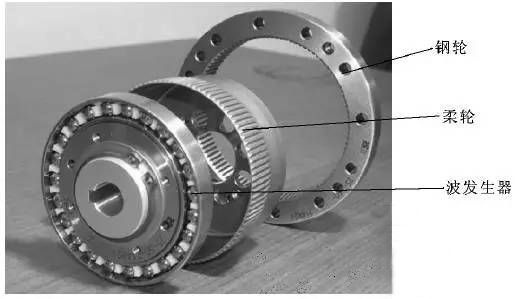

Simply put, the harmonic gear drive consists of three basic components and components

Harmonic generator is composed of a cam and a thin-walled bearing. As the cam rotates, the outer ring of the thin-walled bearing moves in an elliptical shape.

Rigid wheel-is a rigid internal gear.

Flexible wheel-is a thin shell-shaped element with elastic external gear.

Wave generators are usually elliptical cams, install the cams in thin-walled bearings, and then install them in the flex wheel. At this time, the flexible wheel changes from an original circle to an ellipse, and the flex wheels at both ends of the ellipse long axis are in full mesh with the rigid wheel teeth, that is, the external teeth of the flex wheel and the internal teeth of the rigid wheel are along the tooth height Mesh. This is the meshing area. Generally, about 30% of the teeth are in meshing state; the flexible gear teeth and the rigid gear teeth at both ends of the ellipse short axis are completely disengaged, referred to as disengaged; between the long axis and short axis of the wave generator In the different sections of the flexible wheel circumference, some of the flexible wheel teeth gradually withdraw from between the teeth of the rigid wheel and are in a semi-detached state, which is called a bite out.

Harmonic reducer tooth engagement and disengagement

When the wave generator is the active element, the cam rotates in the flex wheel, which causes a controlled elastic deformation of the flex wheel and the thin-walled bearing. At this time, the teeth of the flex wheel enter (mesh) or exit (mesh) during the deformation process The teeth of the rigid wheel are fully engaged at the long axis of the wave generator, while the teeth in the direction of the short axis are completely disengaged.

When the motor drives the wave generator to continuously rotate in the flexible wheel, it forces the flexible wheel to produce continuous elastic deformation, which causes the four states of the flexible wheel teeth to engage-engage-engage-disengage. The original meshing state. This phenomenon is called wrong tooth movement. It is this wrong tooth movement that acts as a reducer to change the high-speed rotation of the input into the low-speed rotation of the output.

For the harmonic gear transmission of the dual-wave generator, when the wave generator rotates clockwise 1/8 turn, the flexible gear teeth and the rigid gear teeth are engaged from the original engagement state, and the original disengaged state becomes Into the state. In the same way, the meshing becomes disengaged, and the meshing becomes meshed, so that the flexible wheel rotates (angular displacement) by 1/4 tooth relative to the rigid wheel; similarly, when the wave generator rotates for another 1/8 cycle, the above process is repeated At this time, the flexible wheel is displaced by one pitch. By analogy, when the wave generator makes one rotation relative to the rigid wheel, the displacement of the flexible wheel relative to the rigid wheel is two tooth pitches.

The process of meshing the flexible gear teeth and rigid gear teeth at the pitch circle is like two purely rolling (no sliding) rings. At any instant, the arc lengths of the two rotating circles on the pitch circle must be equal. Because the flexible wheel has two pitches less than the rigid wheel in the pitch circle length, the flexible wheel must rotate through the angular displacement of the two pitches relative to the rigid wheel during the meshing process. This angular displacement is exactly the output shaft of the reducer Rotate to achieve the purpose of deceleration.

The continuous rotation of the wave generator forces a point on the flexible wheel to continuously change its position. At this point, at any point of the pitch circle of the flexible wheel, with the process of angular displacement of the wave generator, a symmetrical harmonic wave is formed up and down, left and right , It is called: "harmonics".